What are the advantages of electric forklifts? Compared to diesel forklifts

Introduction: Electric forklifts (usually battery-powered industrial vehicles) have become the undisputed mainstream choice for modern warehousing and logistics industries, compared to traditional fuel-powered forklifts (diesel, gasoline/LPG).

Electric forklifts are primarily categorized by their usage scenario:

- Walking electric stackers: Operated by the operator walking behind the electric stacker.

- Ride-on electric stackers: Operated by the operator standing on the stackers.

- Counterbalanced electric forklifts: Operated by the operator sitting in the cab.

- Electric pallet trucks: Primarily used for horizontal cargo handling.

- Warehouse reach trucks: Industrial transport vehicles, a type of warehouse lifting trucks, are forward-moving wheeled transport vehicles used for loading, unloading, stacking, and short-distance transportation of palletized goods. They are used for transporting large items in warehouses and are typically battery-powered. Reach trucks combine the advantages of counterbalanced electric forklifts and stacker trucks, offering environmental protection and energy efficiency, low noise levels, high lift capacity, and a compact operating space.

Diesel Forklift Classification

- Based on the engine type, forklifts can be categorized as diesel, gasoline, and dual-fuel LPG forklifts.

- Based on the operating environment, they can be categorized as diesel and four-wheel drive off-road forklifts.

Similarities of them

Electric counterbalanced types and internal combustion forklifts offer customization of lift height, a range of load capacities from 2 to 10 tons, upgrades to features like side shift and adjustable fork, customization and installation of auxiliary equipment, and tire replacement options (solid tires, pneumatic tires, and non-marking tires).

The advantages of electric forklifts are primarily reflected in the following aspects:

- Core Advantage: Environmental Protection and Zero Emissions

This is the most significant advantage of electric lifter.

- Zero Exhaust Emissions: Warehouse electric forklifts produce no harmful gases (such as carbon monoxide, hydrocarbons, and nitrogen oxides) during operation, making them ideal for use in indoor environments, such as those in the food, pharmaceutical, electronics, and cold chain industries, where air quality is critical. This ensures the health and safety of employees. • Low Noise: Electric motors operate much quieter than internal combustion engines, resulting in an extremely low noise level. This makes them ideal for use in quiet environments, such as libraries, hospitals, office buildings, nighttime operations, and urban warehouses. This reduces hearing loss and fatigue for operators, while also protecting the health of other warehouse workers.

- Compliance with Environmental Regulations: With increasingly stringent global regulations on carbon emissions and environmental protection, many European and American countries have adopted electric lifter for warehouse operations. These vehicles also meet their respective emission standards, such as EU Euro V and the EPA standards in the US and Canada. This has made electric forklifts increasingly popular.

Economic Advantage: Lower Purchase and Operating Costs

For forklifts in the five-ton tonnage range, the initial purchase cost of an electric one is generally lower than that of a comparable fuel-powered lifting machines. Long-term operating costs are also significantly lower, with a service life of approximately 5-10 years.

- Low Energy Cost: Electricity costs significantly less than diesel or gasoline. Depending on usage frequency, its energy costs are typically only 10%-30% of those of a fuel-powered forklift. • Low Maintenance Cost: Electric forklifts have a relatively simple structure, lacking the complex components of internal combustion engines, such as the engine, transmission, spark plugs, air filter, and oil filter. Removing the need for oil and filter changes significantly reduces routine maintenance and spare parts costs.

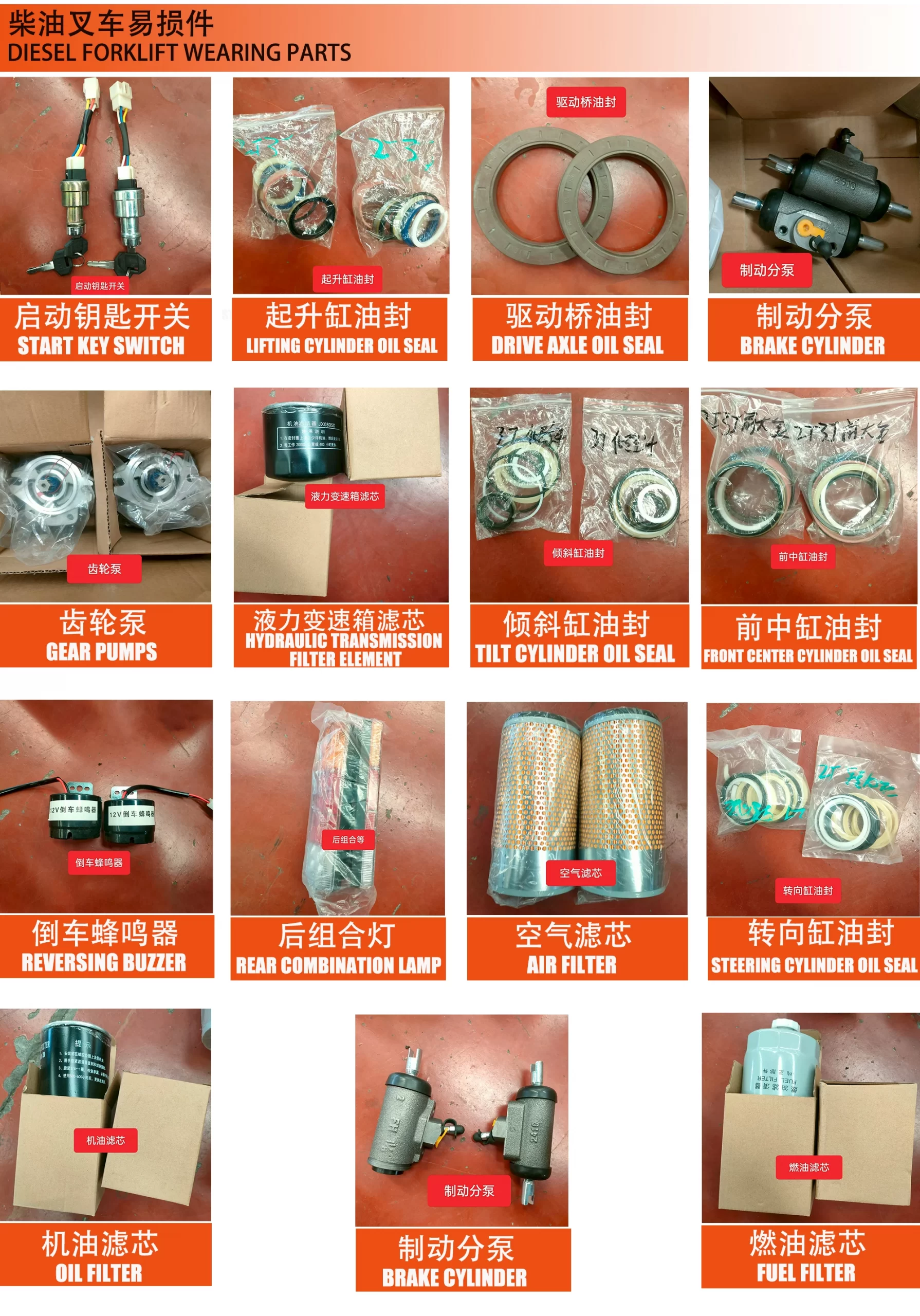

- Minimal Maintenance: Maintenance primarily focuses on the battery, motor, electric forklift controller, and hydraulic system, making them much less troublesome than fuel-powered forklifts. In contrast, fuel-powered forklifts require replacement of a range of components, such as diesel forklift air filters, fuel filters, oil filters, and oil seals.

Performance and Operational Advantages: Efficient and Precise

- Better Operational Experience: Electric forklifts typically use electronic speed control, resulting in smoother starting and driving, precise control, and excellent micro-maneuvering (slow, precise movement), which improves handling efficiency, especially in confined spaces and warehouses with densely packed shelves.

- Energy Regeneration: Advanced electric types lifting machines feature energy recovery during braking, deceleration, and downhill driving, converting some kinetic energy back into electricity and charging it back to the battery, further extending battery life. • Full Power Output: Electric forklifts deliver constant maximum torque at all speeds, ensuring stable power output. Internal combustion engine forklifts, however, lack torque at low speeds, offering significant advantages when starting and climbing hills. Mechanically operated diesel forklifts require variable transmissions to accommodate high and low speeds. Due to the characteristics of the internal combustion engine, the power source can be highly unstable.

- Simple Operation: Electric vehicles are like forklifts with electronic hydraulic gears. Simply push the joystick forward to move forward, and pull back to stop and reverse, making them very convenient. Diesel vehicles, on the other hand, require experienced forklift operators for optimal operation.

Advantages in Work Environment Adaptability

- Improved Indoor Environment: No exhaust emissions significantly improve air quality in warehouses and workshops, preventing heat and odor problems caused by exhaust gas accumulation and reducing energy consumption in ventilation systems.

- Wide Range of Applications: Due to their environmentally friendly nature, electric ones are ideal for indoor warehouse work, but a growing number of electric forklifts are also being developed for outdoor use. • Explosion-proof environments: Electric forklifts are suitable for mining areas and other areas requiring them.

Choosing a Forklift Type

There are many different types of electric forklifts. Customers can choose the right industrial vehicle based on their specific needs, operating habits, and budget. Electric forklifts have a relatively small turning radius and can adapt well to warehouse aisle widths. Their diverse selection and affordable price make them increasingly popular among logistics and warehouse workers. Some electric forklifts are very compact and portable. Internal combustion forklifts offer a limited selection and are relatively bulky.

Summary and Comparison

| Feature | Electric Types | Internal Combustion (Diesel/Gasoline) Fork lift |

|---|---|---|

| Emissions | Zero emissions, suitable for both indoor and outdoor use | Produces exhaust emissions, severely pollutes indoor air |

| Noise | Very low, <75 dB | Very high, >80 dB, significant noise pollution |

| Energy Cost | Low (electricity is cheap) | High (fuel prices are high and volatile) |

| Maintenance Cost | Low (simple structure, no need for oil or filter changes) | High (requires regular maintenance and frequent part replacements) |

| Initial Investment | Higher (mainly due to battery cost) | Relatively lower |

| Operating Experience | Smooth and precise, excellent micro-motion performance | Strong vibration, jerky operation, less precise but relatively powerful |

| Range/Refueling | Requires charging, runtime ~6-8 hours (upgradable to high-capacity batteries) | Fast refueling, takes only minutes, longer continuous operation capability |

| Applicable Environment | Suitable for both indoor and outdoor use; requires explosion-proof models for specific environments | Mainly for outdoor or well-ventilated indoor environments |

Conclusion

Electric forklifts, with their overwhelming advantages of environmental friendliness, energy efficiency, low power consumption, quiet operation, and comfortable operation, have become a standard feature in modern, intelligent warehouses. While their adaptability to sustained high-intensity operations and extremely harsh working conditions may be slightly inferior to that of fuel-powered forklifts, the rapid advancements in battery technology (such as lithium-ion batteries) and motor technology are rapidly narrowing this gap. Electric forklifts offer a more futuristic and cost-effective option, and with a wide variety of options, they are a highly cost-effective warehouse industrial vehicle.