How to maintain an electric forklift?

Electric forklifts are powered by batteries or electric motors. Compared to traditional internal combustion engine forklifts, they offer numerous advantages and features. This article will provide a detailed overview of electric forklifts’ advantages, applications, and development trends.

First, the advantages of electric forklifts primarily lie in their environmental protection, energy conservation, and efficiency. Powered by batteries or electric motors, electric forklifts produce no exhaust emissions, reducing environmental pollution and meeting modern society’s environmental protection requirements. Furthermore, electric forklifts are more energy efficient, achieving higher energy efficiency and significant energy savings compared to internal combustion engine forklifts. Furthermore, electric forklifts are quieter during operation, creating a quieter working environment and enhancing operator comfort and efficiency.

Second, the application of electric forklifts is growing in various fields. In the warehousing and logistics industry, electric forklifts, due to their zero emissions and low noise levels, are widely used in warehouse cargo handling, loading and unloading operations, and other applications. Electric forklifts also play a vital role on factory production lines, improving production efficiency and operational safety. Furthermore, with the development of urban logistics, electric forklifts have become a vital tool for urban distribution, injecting new vitality into urban logistics and transportation.

Electric forklifts are mainly composed of four important parts: hydraulic system, circuit system, motor and battery. In contrast, electric forklifts do not have the complex mechanical structure of internal combustion forklifts. They do not require regular replacement of fuel and air filters, making maintenance relatively simple. Let’s take a look at how to perform daily maintenance on electric forklifts.

I. Pre-Operation Inspection Items:

1. Clean oil, dirt, and dust from exposed parts of the electric forklift, including the body.

2. Inspect the entire electric forklift for oil and water leaks.

3. Check that all onboard tools and accessories are complete.

4. Check that grease, brake fluid, hydraulic oil, and chain oil are sufficient; replenish if insufficient.

5. Inspect and tighten the screws, nuts, and cotter pins of all electric forklift accessories.

6. Inspect the contact and tightness of all electrical system contacts, and clean and polish all contact points.

II. During-Operation Inspections Electric forklifts

- Check the condition and tightness of the tires, steering, and brake systems.

- For daily maintenance of the forklift battery, refer to the maintenance and care for internal combustion forklift batteries.

- Check that the horn, lights, direction switches, and brake switches are functioning properly; and that all indicator instruments are functioning properly.

- Check the hydraulic oil tank for the required oil level and temperature (not exceeding 60°C). Check the hydraulic pump, distribution valve, and hydraulic cylinder for proper operation. Check the main and auxiliary components of the hydraulic system for leakage or seepage.

- Check and adjust the tension of the lifting chains.

- Electric forklifts are generally not waterproof. Do not operate them in the rain to prevent rainwater from dripping into the vehicle’s path and causing a short circuit. During operation, be careful to prevent splashing of water or other liquids. Do not use high-pressure water to flush the electric forklift to avoid affecting the forklift’s electrical system.

III. Maintenance Items After Returning to the Depot:

- Clean the exterior of the electric forklift.

- Check tire pressure.

- Troubleshoot any faults discovered during operation.

- Check the tightness of the fork frame and lifting chain tensioning bolts. If the lifting chain is found to be insufficiently lubricated, lubricate and adjust it promptly.

- The electric forklift’s battery should be charged promptly after use. Do not over-discharge, overcharge, high-current charging, or discharge when insufficiently charged during operation. Doing so will increase resistance, damage the positive and negative plates, and reduce the forklift battery’s capacity, leading to severe operational difficulties.

- Lubricate and adjust the electric forklift’s lifting chain.

- Inspect and tighten loose bolts on all vehicle assemblies.

- Inspect and organize the tools and accessories on board.

- Clean the exterior of the electric forklift battery, check the electrolyte level, and check the cleanliness and tightness of the electrode posts and connecting cables.

Tutorial on Activating a Zero-Voltage Lithium Battery Due to Over-Discharge

Our electric forklifts usually use lithium iron phosphate batteries, which are relatively stable. At the same time, lithium iron phosphate batteries can operate in temperatures between -20 degrees Celsius and 70 degrees Celsius. The battery is a very important part of an electric forklift, so how to maintain and repair the electric forklift battery?

When a lithium battery is locked by the protection board due to zero voltage, the following methods can be tried to activate it. However, safety must be prioritized (if the battery is swollen or leaking, it should be discarded immediately and cannot be activated).

I. Core Principle

The protection board triggers over-discharge protection when the battery voltage drops below a threshold (usually below 2.5V), cutting off the charge-discharge circuit. The key to activation is to replenish the battery cells with a small current until the voltage reaches the

protection board’s unlock threshold (above 2.5V), restoring the protection board to normal function.

II. Activation Steps

1. Prepare Tools

A variable DC power supply (or a low-voltage, small-current charger, such as a dedicated lithium battery activator), a multimeter, and wires (or alligator clips).

2. Identify Positive and Negative Electrodes of the Cells

Open the battery casing (for sealed batteries, locate the positive and negative solder points of the cells; do not connect to the protection board interface). Use the DC voltage setting on the multimeter to measure the cell voltage and confirm it is close to 0V.

3. Replenish with Small Current

Set the variable power supply voltage to 50V and the current to 0.1-0.5A (lower current is safer). For a 48V battery, set the activation voltage to 40V; for a 60V battery, set it to 50V; for a 72-80V battery, set it to 60V.

Use wires to connect the positive terminal of the power supply to the positive electrode of the cell and the negative terminal to the

negative electrode of the cell (never reverse the positive and negative connections). Charge continuously for 10-30 minutes.

4. Check Voltage

Re-measure the cell voltage with a multimeter. If it rises above 2.5V, the protection board has unlocked, and you can stop replenishing power.

5. Normal Charging

Reassemble the battery with the protection board, connect it to the original charger for normal charging, and check if it can charge properly without abnormalities such as overheating or swelling.

III. Notes

- Keep away from fire sources throughout the process and avoid short circuits (connect wires with the power off). If the battery heats up or smokes, stop immediately and discard it.

- If the battery capacity drops significantly after activation (e.g., to less than 50% of its original capacity), the cells aredamaged andshould not bereused, as they pose safety risks.

If activation fails, the cells or protection board are likely damaged, and it is recommended to replace the battery with a new one.

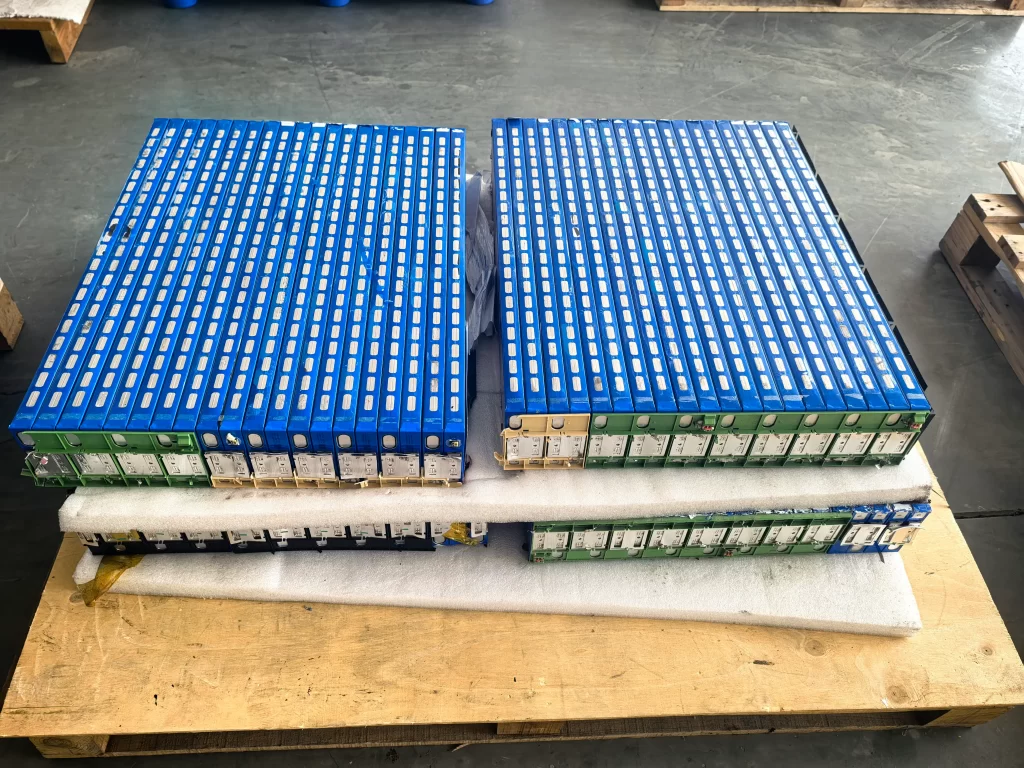

Our electric forklift lithium-ion batteries use the same cells as those from CATL and are equipped with a battery management system (BMS). This system allows users to monitor battery charge, temperature, and health status via a QR code. As a professional electric forklift manufacturer, we offer customized forklifts and batteries.

Our batteries are also equipped with a smart LCD display and communication system, along with storage for water bottles and phones, for a more user-friendly experience.