How to Choose the Right Warehouse Reach Truck? The Ultimate Buyer’s Guide for 2025

Opening Paragraph:

With the development of modern logistics and warehousing, a good warehouse reach truck has become increasingly important. As large warehouses tend to become denser and taller, very high racks are often used to store items to maximize storage space. This is why warehouse forklifts designed for high racking, have emerged. So, what is a warehouse reach truck? It is an industrial transport vehicle and a type of warehouse forklift. It is a forward-moving wheeled transport vehicle used for loading, unloading, stacking, and short-distance transportation of palletized goods. It is used for transporting large items in warehouses and is typically battery-powered. Reach trucks combine the advantages of counterbalanced electric forklifts and stacker trucks, offering environmentally friendly and energy-saving features, low noise levels, high lift capacity, and a compact operating area.

Warehouse reach trucks are core equipment in logistics and production, making the right choice crucial. Choosing the wrong electric forklift can lead to failure to meet user requirements, inefficiency, increased operating costs, and even safety hazards…

This article will systematically guide you through seven key aspects of selecting the electric forwarder forklift that best suits your business needs.

1. Identify Your Core Needs

1.1 Load Capacity

For conventional electric forklifts with a lift height of less than 3 meters, the maximum weight of cargo handled on a daily basis is generally sufficient. However, how should one select the required load capacity for electric lift trucks with a lift height of over 10 meters, such as reach lift trucks? Warehouse reach trucks have a smaller lifting capacity and are often powered by electric motors. These industrial vehicles typically have a load capacity of less than 3 tons, limiting the selection options. However, it’s important to consider the lift heights described below to determine the required forklift capacity. First, measure the maximum weight of your cargo and record it.

1.2 Lift Height

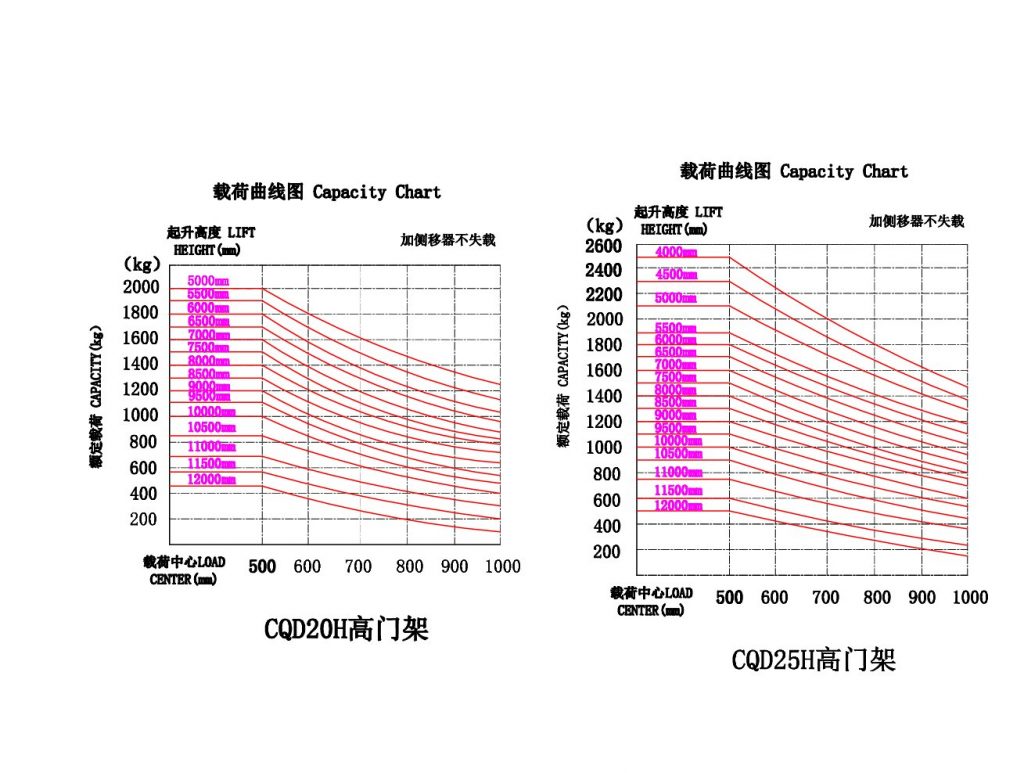

First, measure the maximum height of your warehouse racks. It’s recommended to select a forklift with a lift height slightly higher than this. Contact the warehouse lift truck manufacturer and ask them to provide the forklift’s load diagram. The reach truck load diagrams we provide are as following, for a 2-ton and a 2.5-ton.

With a forklift load center of 500mm and a lift height of 10 meters, a 2-ton forklift can carry 600kg, while a 2.5-ton forklift can carry 800kg. Therefore, you can choose the most cost-effective indoor forklift based on your cargo needs. Note that if you want to reach a 2-ton load at a height of 10 meters, this type of warehouse lift is almost impossible. Therefore, choose the appropriate equipment based on your specific needs.

1.3 Working Conditions

Determine the forklift’s intended use: indoor or outdoor? Also, check the floor’s flatness and aisle width. A reach truck is an indoor electric forklift capable of performing high-level stacking operations in confined working spaces. This is something that counterbalanced forklifts and stacker trucks cannot compare to. Counterbalanced forklifts of the same tonnage require more space, while stacker trucks operate at relatively low heights. Therefore, for stacking high racks in limited working spaces, a reach truck is the best choice because it is a narrow-aisle forklift. Cold storage or room temperature environments? We are a professional warehouse reach truck manufacturer and can manufacture cold storage forklifts for you.

2. Choosing Power Type: Lithium Battery vs. Lead-Acid Battery

2.1 Advantages of Lithium Battery Forklifts

The advantages of lithium battery forklifts include fast charging, longer service life, maintenance-free operation, higher efficiency, and environmental friendliness. However, lithium batteries are relatively expensive.

2.2 Suitable Applications for Lead-Acid Battery Reach Trucks

Low initial investment, suitable for single-shift operations, and with well-equipped charging facilities. Lead-acid battery forklifts are relatively inexpensive lifting equipment. Our electric forklifts use maintenance-free lead-acid dry batteries. Compared to traditional lead-acid batteries, their electrolyte consumption is significantly lower, and no acid or water additions are required for maintenance during use.

3. Examining Key Performance and Configurations

3.1 Battery Life and Charging Solutions

Relatively speaking, lithium batteries have longer battery life than lead-acid batteries, but lead-acid battery forklifts are safer and more stable than lithium battery forklifts.

3.2 Drive Type: Three-Wheel vs. Four-Wheel

Three-Wheel: Smaller turning radius, more maneuverability, suitable for narrow aisles.

Four-Wheel: Greater stability, suitable for heavy loads and uneven surfaces.

Currently, we generally use four-wheel electric forklifts, which are more stable. There are also four-way electric forklifts that can further reduce the turning radius and accommodate the smallest aisles.

3.3 Mast Types and Other Additional Configurations

The general industry standard mast is a two-stage mast. For forklifts over 7 meters, a three-stage mast with full free-wheeling function is used. You can also customize this forklift with a fully free mast to suit low-ceiling warehouses, etc.

4. Focus on Safety, Comfort, and Intelligence

4.1 Safety Features

Forklifts can be equipped with an OPS/SPRS audible and visual alarm system, and our forklifts also feature an emergency power-off switch to ensure safety and stability.

4.2 Operator Ergonomics

Warehouse forklifts can be divided into sit-down trucks and stand-by trucks. Sit-down trucks offer comfortable seats, shock absorption systems, and intuitive control interfaces to reduce fatigue and improve efficiency.

You can also choose a stand-by reach truck, which is more suitable for your operating habits.

4.3 Intelligent Management System (IoT & Fleet Management)

We also offer forklifts with fleet management systems that monitor forklift status, efficiency, and data, a trend in modern warehouses.

5. Forklifts Brand, Service, and Total Cost of Ownership (TCO)

5.1 Brand and After-Sales Service

When choosing a forklift, you should not only consider the price, but also the quality and after-sales service.We emphasize the importance of localized after-sales service and fast parts delivery, not just price.

5.2 Calculating the Total Cost of Ownership

Users do not only consider the purchase price but also need to calculate the total cost, including electricity, maintenance, and depreciation.

6. Summary: Your Purchasing Decision Checklist

- Step 1: Confirm that my load capacity and lift height are ______.

- Step 2: My operating conditions are (indoor/outdoor/cold storage) ______, and the aisle width is ______.

- Step 3: My shift schedule is ______, so I prefer (lithium battery/lead-acid) ______.

- Step 4: My budget range is ______, and I prioritize (initial investment/long-term TCO) ______.

Final Recommendation: Contact two or three suppliers, provide your requirements, and request demonstrations and solutions.

7. FAQ Section – Schema markup preferred

Q: Which is better, an electric forklift or a reach truck?

A: Electric forklifts have a lifting capacity of up to 10 tons and can be used indoors. However, their maximum lifting height is limited to 7 meters. They are not suitable for tall racks and narrow aisles. Warehouse reach trucks, while capable of lifting up to 3 tons, can reach heights of over 10 meters, making them more suitable for modern warehouse management.

Q: How much does a warehouse reach truck cost?

A: Approximately $30,000 USD, depending on the load capacity, customized lift height, features, and battery capacity.

Q: What is the lifespan of a reach truck?

A: Typically 5-10 years, depending on usage, maintenance, and battery type.