Electric Counterbalance Forklifts vs. Reach Trucks: How to Choose the Right Equipment for Your Warehouse

In today’s fast-paced logistics environment, selecting between electric counterbalance forklifts and reach trucks is a critical decision that impacts operational efficiency. While both machines share core functionalities like lifting heavy loads and battery-powered operation, their specialized designs cater to distinctly different warehouse needs.

Key Differences in Design and Functionality

Counterbalance Forklifts: The Versatile Workhorse

- Balanced Weight System: Features a rear counterweight for stability without outriggers

- All-Terrain Capability: Performs equally well indoors and on rough outdoor surfaces

- Attachment Versatility: Compatible with numerous accessories including:

- Clamping attachments (bale clamps, drum handlers)

- Side shifters and fork positioners

- Push-pull devices for slip-sheet handling

- Rotators and tippers for specialized applications

- Crane arms and personnel platforms

Reach Trucks: The Space-Saving Specialist

- Compact Design: Operates in aisles as narrow as 1.6m

- Vertical Reach: Extending masts access heights up to 16m

- Limited Attachments: Primarily uses specialized forks (triple forks or scissor forks) due to narrow-aisle constraints

Performance Comparison

| Feature | Counterbalance Forklift | Reach Truck |

| Aisle Width | ≥3m | 1.6–2m |

| Max Lift Height | ≤7m | Up to 16m+ |

| Load Capacity | 1–7 tons | 1–3 tons |

| Terrain Adaptability | All surfaces | Smooth floors only |

Selection Guide: 5 Key Considerations for Lifters

- Load Requirements:

- ≤3 tons: Both options work

- 3 tons: Requires counterbalance forklift

- Lift Height Needs:

- ≤7m: Suitable for both

- 7m: Reach truck recommended

- Operating Environment:

- Uneven/outdoor: Counterbalance forklift

- Narrow aisles: Reach truck

- Space Constraints:

- Measure minimum aisle width and turning radius

- Budget Factors:

- Counterbalance forklifts generally more cost-effective

- Reach trucks offer better ROI in high-density storage

Why Choose Our Equipment Solutions?

Our reach trucks deliver exceptional value through:

- Durable H-Beam Mast Construction for safe high-level operation

- Premium Curtis Control Systems (U.S. made) for precision handling

- Energy Recovery Technology saving 15-30% in power costs

- Custom Configuration Options to match specific workflows

Our electric forklift’s advantage:

- Features a thickened steel rear axle and a transverse drive unit, facilitating a low center of gravity design for the entire vehicle

- Brushless AC motor: high power, high torque, low noise, long service life, energy regeneration: 30% energy regeneration efficiency during braking

- Maintenance-free lead-acid dry cell battery, easy maintenance and long battery life with up to 3000 charge and discharge cycles.

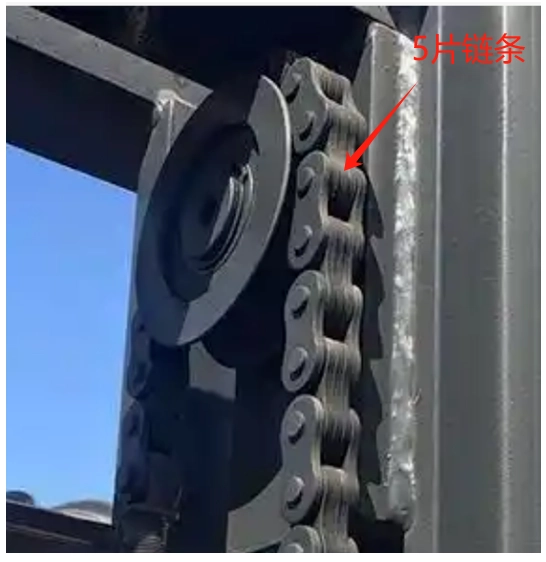

- Integrally forged forks and thickened 7-section chain

Conclusion: Matching Equipment to Your Operational Needs

For warehouses prioritizing space optimization and high-level storage, reach trucks provide unbeatable efficiency in narrow-aisle environments. Counterbalance forklifts remain the superior choice for versatile material handling across diverse terrains and heavier loads.

Pro Tip: Many operations benefit from maintaining both equipment types – using reach trucks for daily warehouse operations and counterbalance forklifts for loading/unloading and outdoor tasks.

Ready to optimize your material handling? Contact our experts for a personalized equipment assessment and discover how our solutions can transform your warehouse productivity.