How to Choose a Forklift That Matches Warehouse Aisles? Safe Forklift Operation?

When using a forklift or electric forklift in a warehouse, it is essential to consider the forklift’s minimum turning radius and aisle width. Designing a reasonable aisle ensures safe and efficient forklift operation within the warehouse.

How to Calculate Forklift Aisle Width?

First, it is important to understand the key concepts related to forklift aisle calculation. Forklifts are widely used industrial vehicles in the logistics and warehousing sectors. Scientifically determining minimum aisle dimensions and selecting appropriate forklifts for different warehouse layouts is critical.

Minimum Turning Radius vs. Right-Angle Stacking Aisle Width

- Forklift Minimum Turning Radius R:

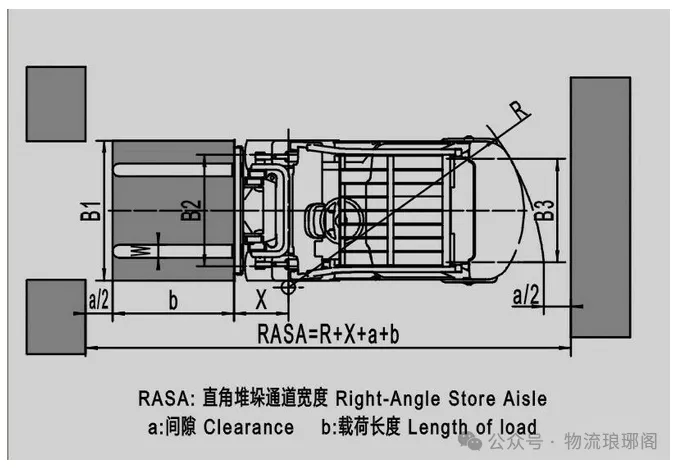

When a forklift is unloaded and moving at low speed with the steering wheel fully turned, the minimum distances from the outermost and innermost sides of the vehicle to the turn center are referred to as the minimum outer turning radius and minimum inner turning radius, respectively. - Right-Angle Stacking Aisle Width (RASA):

This is the aisle width required for a forklift to make a 90-degree turn. It represents the straight-line distance between two rows of racks in an indoor aisle where the forklift operates.

Explanation: The right-angle stacking aisle width is a key indicator of whether a forklift has sufficient space to operate after entering the work area. Simply put, it is the distance between two obstacles (e.g., shelf rows) when the forklift moves straight into position and turns 90 degrees to reach the load.

Calculating Shelf Aisle Width for Forklift Operations

Calculating warehouse aisle width requires comprehensive consideration of multiple factors, including the type of handling equipment, cargo size, and safety clearances. Below are specific calculation methods and standards:

1. Calculation Based on Handling Equipment Type

Examples: Land loader / reach forklift / electric pallet truck / double-deep forklift, etc.

Calculation formula:

Shelf aisle width RASA = turning radius R + front overhang X + fork/pallet length b + safety clearance a

Parameter Explanation:

- Turning radius R: Generally the maximum distance from the front wheel center to the counterweight. This data is available in the product manual.

- Front overhang X: Distance from the center of the forklift’s front wheel to the front wall of the forks.

- Cargo length b: The larger value between cargo length and fork length.

- a ≥ 0.2m: Safety clearance, with at least 0.1m on each side.

Important Notes:

- Fork/pallet length should be calculated based on actual conditions. Use the maximum value as each forklift and location may vary.

- Theoretical turning radii may be similar across brands, but actual operational results differ significantly due to overall forklift maneuverability.

- A safety gap of 20mm is generally allowed in both front and rear directions. Operator skill and efficiency should also be considered.

- Experienced operators require less time and fewer maneuvers in the same aisle width compared to novices. For less experienced operators or tight schedules, it is advisable to increase the safety gap.

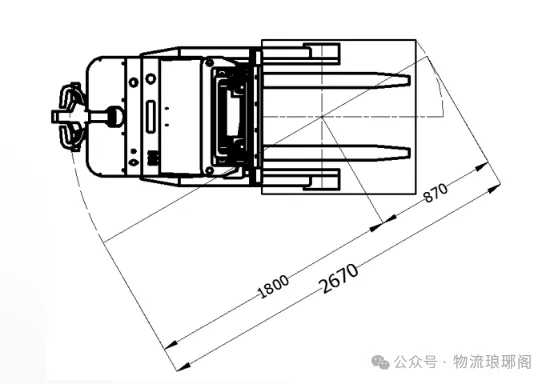

For example, as shown in the figure below, if the turning radius is 1800mm and the minimum right-angle stacking aisle width is 2670mm, the recommended aisle width is 2670mm + 200mm (safe operating clearance). An additional 100mm may be added for an extra safety margin.

Note: Common forklift aisle widths for warehouse racks:

- Scissor-type forklifts (double-deep racking): typically 3.5m to 3.6m.

- Reach trucks and counterbalanced forklifts (drive-in racking): reach trucks require about 3-3.3m, while counterbalanced forklifts generally need over 3.5m, often 4m.

2. Calculation Based on Aisle Usage

- One-Way Aisles:

Aisle width = forklift width (including cargo width) + 0.6m safe working distance.

Example: For small forklifts, aisle width is generally 2.4m to 3.0m. - Two-Way Aisles:

Aisle width = 2 × forklift width (including cargo width) + 0.9m safe working distance.

Example: Two-way aisle width is generally 4.8m to 6.0m. - Manual Access Aisles:

If only manual movement is required, aisle width is typically 0.8m to 1.2m. If mechanical handling equipment is used, the aisle width must be increased based on equipment specifications.

If carts are used, the aisle width should be based on the cart’s actual width plus a margin, generally 2m to 2.5m.

3. Aisle Calculation for Lightweight Shelves

For light-duty shelves, aisle width calculation is relatively simple:

Formula: Aisle Width = n × w + 0.1 × (n + 1)

Parameter Explanation:

- n: Number of vehicles handled simultaneously (usually 1 or 2).

- w: Width of the picking cart.

- 0.1 meter: Safety space between each vehicle.

4. Special Cases

When using specific handling equipment (e.g., stackers in automated warehouses, narrow-aisle forklifts), aisle width must be determined based on the equipment’s size, operating space, and turning radius. This often requires precise measurement and design.

Example: Narrow-Aisle Warehouse Racking

Aisle width in narrow-aisle setups is typically narrower than standard racking but must meet the forklift’s minimum turning radius (e.g., three-way stacking forklifts) and cargo size. Aisle widths generally range from 1.6m to 2.0m, depending on forklift type and cargo dimensions.

5. Signage and Lighting

- Evacuation routes should be clearly marked on the aisle floor to ensure visibility.

- Aisles must be well-lit to ensure safe operation.

6. Regulatory Compliance

All aisle designs must comply with local fire safety, production safety, and building regulations. Emergency aisles must never be obstructed.

Warehouse Forklift Safety Regulations

- Do not operate between the mast and overhead guard.

- Always turn on operating lights in dark areas to ensure adequate lighting.

- Do not carry passengers on the forks or on the forklift.

- Do not play or frolic while operating the forklift.

- Honk the horn and slow down when turning blind corners.

- Remember that forklifts have rear-wheel steering; be cautious when turning.

- Observe height restrictions when entering and exiting factories and warehouses.

- Avoid high-speed turns or sharp maneuvers.

- Do not operate in aisles with unknown loads.

- Before leaving the forklift, turn off the power, remove the key, lower the forks fully to the ground, and apply the parking brake.

- Pay attention to the direction of travel when driving up or downhill without a load.

- Pay attention to the direction of travel when driving up or downhill with a load.

- Do not perform maintenance under the working device unless it is mechanically secured.

- If cargo obstructs vision, have a designated person guide when traveling up or downhill.

- Do not use open flames or smoke when refueling or checking the forklift battery.

- Only use inspected and approved forklifts for operations.

- Perform regular maintenance to keep the forklift in good condition.

- Conduct daily inspections before operation.

- Adjust fork width to match the pallet size. Do not handle overly wide or high items.

- Always wear a safety belt when operating.

- Observe all factory traffic signs.

- Keep the load as low as possible and tilt the mast backward.

- Ensure loads are not tilted during loading and unloading.

- Prohibit unauthorized personnel from entering the working area, including under raised forks, behind the forklift, and in the rear turning zone.

- Ensure adequate visibility when operating with a load. Reverse if the load blocks your view.

- Never use forklifts to carry passengers or hold goods by hand.

Forklift Safety Distance Management Measures

1. Safe Distance Between Forklifts and Pedestrians

- Maintain a horizontal distance of at least 3 meters; keep a distance of at least 5 meters in the direction of travel.

Management Measures:

- Set up 1.5-2 meter wide isolation aisles marked with yellow lines.

- Install audible and visual alarms that activate when the distance between a forklift and a pedestrian is less than 2 meters.

- Restrict pedestrian access to high-risk areas during peak hours to reduce mixed traffic risks.

2. Safe Distance Between Forklifts and Racks

- Maintain at least 10 cm between the forks and the rack during loading/unloading, and at least 50 cm lateral distance when turning.

Management Measures:

- Install 50-100 cm high anti-collision guardrails at rack ends.

- Equip forklifts with position detection sensors for real-time operator alerts.

- Mark red warning signs on the bottom of racks to highlight high-risk areas.

3. Safe Operating Distance Between Forklifts

- Maintain 3-4 meters when traveling in the same direction; keep at least 5 meters between forklifts operating in the same area.

Management Measures:

- Implement one-way traffic rules in narrow aisles.

- Install laser sensors to remind operators to maintain safe distances.

- Apply zoning management in high-traffic areas to reduce collision risks.

4. Safe Distance Between Forklifts and Fixed Equipment

- Maintain a minimum distance of 1 meter, increasing to 1.5 meters in high-volume operation areas.

Management Measures:

- Install anti-collision barriers around equipment to define forklift operating boundaries.

- Fit anti-collision devices on equipment bases to reduce low-impact collision risks.

5. Safety Standards

- Area Planning: Use a warehouse map to mark forklift operating zones, pedestrian aisles, and equipment areas with distinct colors.

- Physical Protection: Install 1.2-meter guardrails between pedestrian and forklift areas. Place anti-collision bollards or cushions near rack ends and fixed equipment.

- Line Management: Use floor tape (yellow for forklift lanes, blue for pedestrian lanes) to demarcate traffic lanes.

- Forklift Safety Alarm System: Equip forklifts with anti-collision base stations and alarms. Operators wear wearable terminals that trigger alerts when safe distances are breached.

- Monitoring System: Install cameras and convex mirrors at key intersections and blind spots to improve situational awareness.

Summary

Selecting the right forklift for your warehouse aisles involves understanding key metrics like the minimum turning radius and right-angle stacking aisle width. Proper calculation of aisle dimensions, adherence to safety regulations, and implementing effective distance management measures are essential for safe and efficient forklift operations. Always prioritize compliance with local regulations and invest in safety infrastructure such as signage, alarms, and physical protections to minimize risks and enhance productivity.