Extend Your Electric Forklift Lifespan with These Pro Tips

Electric forklifts are core equipment in logistics and production, and their lifespan directly impacts a company’s return on investment and operational stability. Many users believe that extending lifespan relies mainly on “frequent maintenance,” which is certainly true, but the daily usage habits of forklift operators often have a more profound impact on equipment lifespan. Some seemingly minor operational differences can accumulate over time, leading to drastically different equipment condition and lifespan. As a manufacturer specializing in forklift production and customization, Senchi Machinery, based on long-term service experience, has found that certain details in these habits are particularly easy to overlook. This article, drawing on industry experience, outlines eight key habits to provide you with tips on extending forklift lifespan.

Habit 1: Smooth Starts and Gentle Operation

Why it’s important: If a forklift starts, accelerates, or turns too rapidly, it will severely impact the drive axle, gearbox, and hydraulic system, accelerating the wear of internal components (such as gears and clutch plates). Correct practice: Operate the accelerator pedal and steering control slowly and smoothly, avoiding sudden starts and stops. When turning, especially under full load, be sure to slow down in advance.

Habit 2: Adhere to the load curve and strictly prohibit overloading

Why it’s important: Every forklift has a clearly defined rated load curve (the relationship between the load center distance and the permissible weight). Overloading or having the load center of gravity too far away will seriously damage the frame structure, cause front axle deformation, and even lead to rear-tipping accidents. Correct practice: Before operation, always confirm the weight and center of gravity of the load to ensure it is within the forklift’s rated load capacity. Never take chances and “try it out.”

Habit 3: After electric forklift operation, the forks must be fully lowered to the ground (Crucial habit)

Why it’s important: This is an easily overlooked point. Many operators, for convenience, only lower the forks a short distance off the ground when finishing work or temporarily leaving. This keeps the lifting chain and hydraulic system under constant stress, accelerating chain stretching and the aging and fatigue of hydraulic seals. More importantly, this poses a significant safety hazard (such as pedestrian collisions). Over time, this will lead to premature mast deformation and internal leakage in the hydraulic cylinders. Correct Practice: Before the end of any work cycle or before the operator leaves the forklift, always make it a habit to fully lower the forks to the lowest position to release stress on the entire lifting system.

Habit 4: Avoid Improper “Shovel In” and “Lift Up” Actions

Why is this important: Violently striking the bottom of the pallet with the fork tips, or forcibly lifting the pallet before the forks are fully inserted, will instantly generate enormous torque on the forks, mast, and chain, causing cracks at the fork root and deformation of the mast. Correct Practice: Align the forklift with the pallet opening, slowly drive the forklift in a straight line, and allow the forks to be fully and horizontally inserted into the bottom of the pallet before lifting.

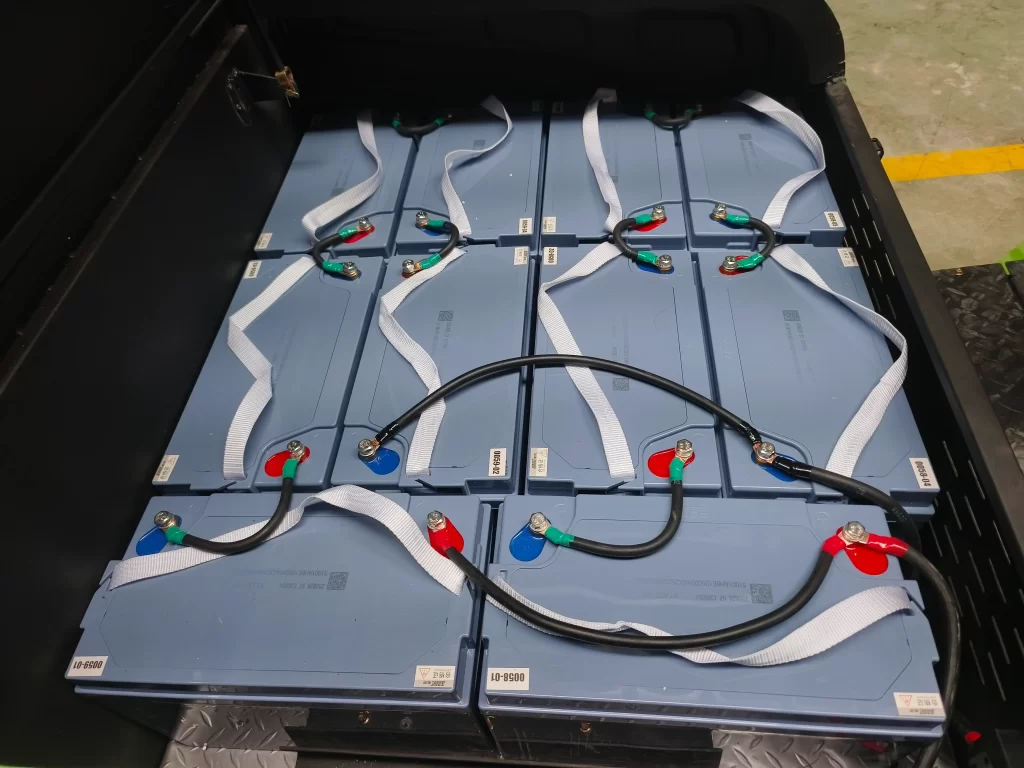

Habit 5: Maintain a Scientific Battery Maintenance Routine of electric forklift

Electric Forklifts: Avoid completely discharging and then recharging the battery. Follow the “shallow charge, shallow discharge” principle, charging the battery promptly when the charge level is below 20%-30%. Avoid overcharging the battery, as this will damage the forklift battery. Regularly check the electrolyte level (lead-acid batteries) and clean the terminals. We are a professional forklift manufacturer, providing forklifts with maintenance-free lead-acid batteries, saving you maintenance costs.

Habit 6: The “One-Minute Check” Before and After Daily Operations

Strictly follow the electric forklift’s daily inspection checklist.

Core Items:

- Before Operation: Check tire pressure and wear, dashboard warning lights, brake function, lights and horn, and for any signs of oil (fluid) leaks.

- After Operation: Clean the vehicle body, especially dust on the radiator and hydraulic valve blocks, and check for any new looseness, abnormal noises, or damage. This habit helps detect small problems early, preventing them from developing into major malfunctions.

Habit 7: Strictly Adhere to Periodic Professional Maintenance of electric forklifts

Why it’s Important: Routine operation and inspections cannot replace professional, in-depth maintenance. The maintenance cycle set by the manufacturer is based on scientific calculations of component wear and lubricant life. Correct Practice: Regardless of whether the equipment appears normal, it is essential to strictly adhere to different levels of regular professional maintenance, such as daily, 250-hour, 500-hour, and 1000-hour maintenance, based on usage hours or calendar time. This includes the testing and replacement of hydraulic fluid, transmission fluid, and brake fluid; torque verification of critical fasteners; and in-depth inspection of electrical systems.