Electric Forklift Charging Solutions: Fast Charging vs. Battery Swap

What is an Electric Forklift?

Definition and Working Principle:

An electric forklift is powered by rechargeable batteries (such as lithium-ion or lead-acid batteries) and driven by an electric motor to perform cargo loading, unloading, transportation, and stacking. Its main components include the battery, motor, control system, hydraulic system, operator cab, chassis, and forks. During operation, the forklift converts electrical energy from the battery into mechanical energy to drive the motor for travel and lifting operations.

Therefore, electric forklift energy sources are primarily categorized into lead-acid batteries and lithium batteries, with hybrid batteries also available. This primarily involves charging solutions for these two battery types.

Lithium Batteries

Lithium batteries for electric forklifts are mainly lithium iron phosphate (LFP) batteries. LFP batteries utilize lithium iron phosphate (LiFePO4) as the cathode material and graphite as the anode. LFP batteries offer excellent electrochemical performance, thermal stability, low resistance, and extended lifespan, making them among the safest lithium batteries available. They are used in forklifts, heavy-duty vehicles, light electric vehicles, and specialty vehicles.

Compared to ternary lithium batteries, LFP batteries are more stable and secure while maintaining high energy density.

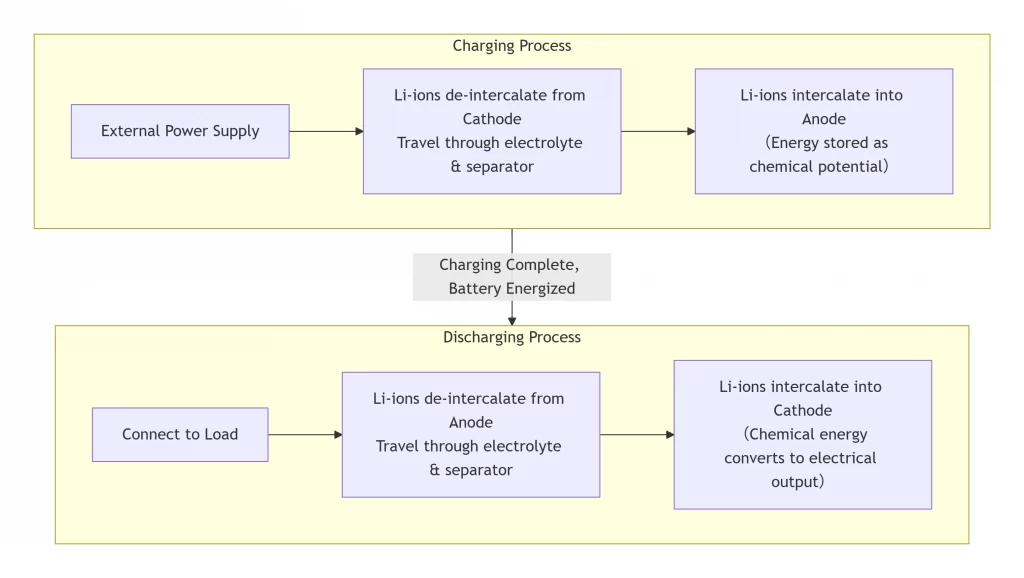

The working principle of lithium batteries is illustrated below:

- Cathode (Positive Electrode): Typically composed of lithium-containing metal oxides (e.g., lithium cobalt oxide, lithium iron phosphate), serving as one of the “storage sites” for lithium ions.

- Anode (Negative Electrode): Usually made of graphite, acting as the other “storage site” for lithium ions.

- Electrolyte: A liquid or solid medium between the cathode and anode that allows free passage of lithium ions while blocking electrons.

- Separator: A porous membrane physically separating the electrodes to prevent short circuits, while its micro-pores permit lithium-ion passage.

This operating principle directly determines several key advantages of lithium batteries:

- Rechargeable: Because lithium-ion movement is a fully reversible chemical reaction.

- High Energy Density: Lithium is an extremely lightweight and reactive metal, enabling greater energy storage within smaller weight and volume.

- High voltage: A single cell typically delivers 3.2V to 3.7V, surpassing nickel-metal hydride and lead-acid batteries.

Consequently, lithium-ion electric forklifts offer these benefits:

- Supports rapid charging: Enabled by lithium ions’ rapid migration within the electrolyte. Capable of fast charging at 220V or 380V industrial power sources—a capability unavailable in lead-acid battery forklifts. As a professional forklift manufacturer, we offer customization for lithium batteries and fast chargers, providing high-quality, cost-effective logistics handling solutions.

- Long cycle life: The positive and negative electrode materials exhibit high structural stability during repeated ion insertion/extraction cycles.

- High depth of discharge: The insertion structure of lithium ions in the negative graphite electrode is relatively stable, allowing more ions to participate in the reaction without damaging the battery. This enables greater energy storage and discharge capacity than lead-acid batteries of the same volume.

Disadvantages of Lithium-Ion Forklifts

Some drawbacks of lithium-ion batteries include:

Significantly higher cost compared to lead-acid batteries.

They are susceptible to thermal runaway, meaning they may catch fire. Therefore, lithium-ion forklifts are subject to strict transportation regulations. However, our implementation of a Battery Management System (BMS) enables effective temperature monitoring.

Overview of Lead-Acid Batteries

Lead-acid batteries were the first commercially available rechargeable batteries. Invented in 1859, they remain widely used for various applications today. Unlike lithium-ion batteries, lead-acid batteries are inexpensive and are often considered a more cost-effective option for delivering high-capacity power.

What Are Lead-Acid Batteries and How Do They Work?

A lead-acid battery is a rechargeable battery that typically uses porous lead as the negatively charged anode and lead oxide (PbO₂) as the positively charged cathode. Both electrodes are immersed in an electrolyte consisting of an acidic solution of dilute sulfuric acid. Immersing the electrodes in the electrolyte triggers a chemical reaction. Chemical reactions within the battery release electrical current flowing through the electrodes. Lead-acid batteries find widespread use in electric vehicles, motorboats, electric scooters, emergency lighting, and more. With advancements in motor and battery technology, lead-acid batteries have also become viable for forklifts, serving as both the power source and counterweight for electric forklifts.

Below is a comparison of lithium iron phosphate batteries and lead-acid batteries for electric forklifts.

| Comparison Dimension | Lead-Acid Battery | Lithium Battery | Prevailing Side |

| Cost (Initial) | Low | High, approximately 1.5 times that of lead-acid batteries | Lead-Acid Battery |

| Lifespan | 3000 cycles | Long, lithium iron phosphate (LFP) can exceed 4000 cycles, 10+ years | Lithium Battery |

| Weight & Energy Density | Heavy, low energy density | Light, high energy density, smaller volume | Lithium Battery |

| Depth of Discharge (DOD) | ~50%, susceptible to damage from over-discharge | Up to 80% or higher, larger effective capacity | Lithium Battery |

| Charging Speed | Slow, requires 10+ hours | Fast, ranging from a few minutes to 3 hours | Lithium Battery |

| Safety | More stable than lithium batteries, higher safety for warehouse and indoor operations. | Thermal runaway and fire risk exists, but Battery Management System (BMS) can mitigate. However, transportation is more challenging. | Context-Dependent |

| Environmental Impact | Contains lead and acid, highly toxic, improper disposal causes significant pollution. | Longer lifespan reduces replacement frequency, but requires specialized recycling. | Lithium Battery |

| Maintenance | Flooded types require regular maintenance. We provide maintenance-free lead-acid batteries. | Essentially maintenance-free | Comparable |

Electric Forklift Charging Solutions: Fast Charging and Battery Replacement

A key limitation of electric forklifts is their inability to operate continuously for 24 hours. When depleted, they require charging before reuse, unlike diesel forklifts that can refuel and work extended periods (over 24 hours). Therefore, charging and battery rotation solutions are critical for warehouse logistics operations.

Electric Forklift Fast Charging

Due to the characteristics of lead-acid and lithium batteries, only lithium-battery forklifts support fast charging—lead-acid batteries do not. Our electric forklift fast-charging solutions include both batteries and chargers. For example, with an 80V 300Ah lithium iron phosphate battery forklift, we can customize this forklift paired with an 80V 60Ah fast charger, enabling a full charge within 5 hours.

Battery Replacement for Electric Forklifts

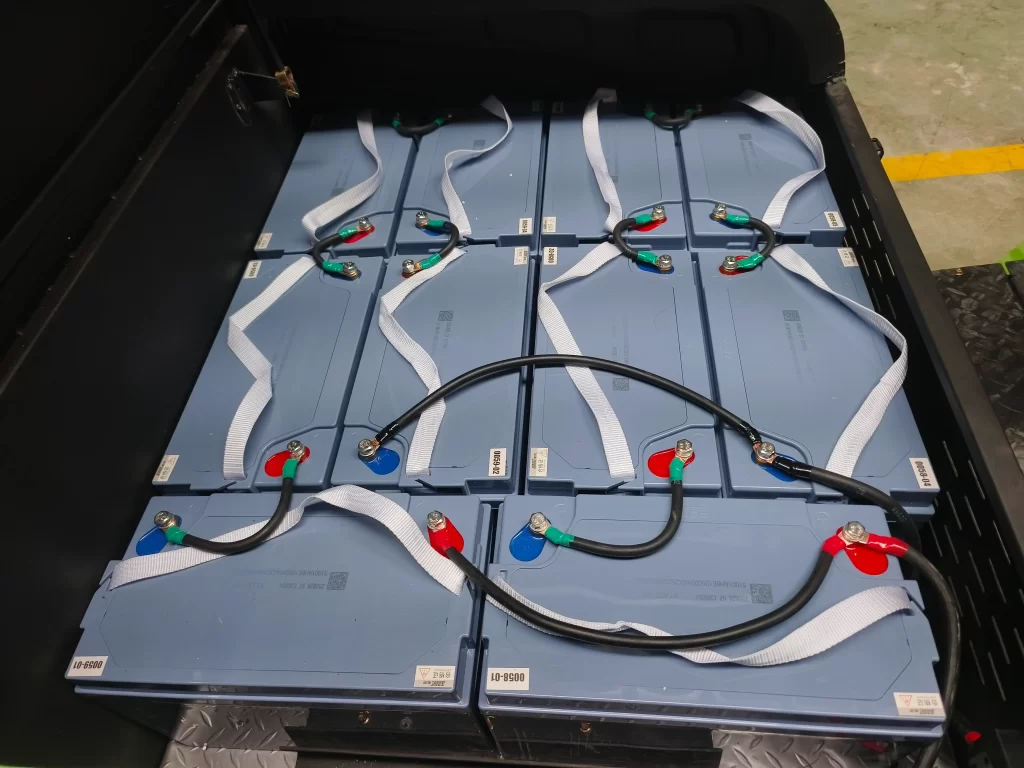

For electric forklifts, preparing an additional battery or multiple spare batteries allows for quick swaps when power runs low, ensuring uninterrupted operations.

Alternatively, deploying a second electric forklift for shift work eliminates the hassle of battery swaps and saves time.

You may also opt for high-capacity forklift batteries, which extend battery life and operational hours, allowing overnight charging. As a professional forklift manufacturer, we support customization of high-capacity electric forklift batteries.

The above outlines several electric forklift charging solutions we propose. You may select the most suitable option based on your requirements.

Summary

Electric forklifts, valued for their eco-friendly operation, are indispensable industrial vehicles in indoor material handling solutions. Consequently, their charging solutions are equally critical. In summary, lithium-ion battery forklifts offer advantages in fast charging, high-capacity batteries, battery management, and portability, making them the optimal charging solution. However, they may be slightly less advantageous than lead-acid battery forklifts in terms of transportation and safety.