Are electric forklifts worth it?

To answer this question, we first need to clarify what electric forklifts are.

Forklifts are essential tools for mechanizing logistics operations, reducing the workload of workers in lifting and improving operational efficiency. They are highly versatile, maneuverable, and have a wide range of motion. With the advancement of science and technology, electric forklifts are becoming increasingly popular as a new energy source.

What is an electric forklift?

The concept of an electric forklift

An electric forklift is a forklift that operates using electricity. It uses a battery as its power source, driving the travel motor and hydraulic system motor, enabling travel and loading and unloading operations. Electric forklifts are currently used in a variety of industries, including manufacturing, transportation, warehousing, postal services, wholesale and retail, and have become a versatile and diverse range of mechanical equipment for logistics, transportation, loading and unloading, and warehousing.

Types of Electric Forklifts

Based on their power source, forklifts can be categorized as internal combustion forklifts, electric forklifts, and manual forklifts. Internal combustion forklifts are further divided into standard internal combustion forklifts, heavy-duty forklifts, container forklifts, and side loader forklifts. Electric forklifts include electric counterbalanced forklifts and electric warehouse forklifts. Electric warehouse forklifts can be categorized into electric reach trucks, electric pallet trucks, electric stacker trucks, and other electric warehouse forks. Based on their structural features, forklifts can be categorized into reach trucks, reach trucks, order pickers, rough terrain forklifts, stand-up forklifts, and seat-on forklifts.

Electric Counterweight Forklifts

These industrial vehicles are equipped with a counterweight at the rear and are battery-powered. They can be equipped with various forklift attachments. Many people choose electric counterbalanced forklifts for their environmental friendliness, quietness, and ease of operation, but sometimes also for their price.

Electric Pallet Truck

This electric truck is an upgrade from a manual truck, featuring a combination lock and easy operation.

Electric Stacker

An electric stacker truck is an electric forklift with a small turning radius. This warehouse handling vehicle is maneuverable and can navigate narrow warehouse aisles. However, its maximum rated load capacity is approximately 3 tons. It can be divided into stand-up stackers and walk-behind models.

Reach Truck

This warehouse electric forklift’s mast or fork can move forward and backward, extending beyond the front wheels to pick up and drop off loads. During travel, the forks retract with the load, keeping the center of gravity within the support surface. This is why it’s called a warehouse reach truck. Reach trucks have two outriggers that extend forward for stability. Also known as narrow aisle forklifts (VNA), this vehicle features a small turning radius, high lift capacity, large payload, and a compact size, making it suitable for dense warehouses and logistics centers.

Electric forklifts: Worth it? Electric counterbalanced forklifts vs. diesel forklifts?

Electric counterbalanced forklifts are increasingly replacing traditional internal combustion forklifts due to their environmental friendliness, quietness, cost-effectiveness, and advanced intelligence. But does the quality of electric forklifts justify their price? What are the advantages and disadvantages of electric forklifts compared to diesel forklifts? These are questions everyone should consider when choosing a forklift.

Below, I will briefly discuss the differences between electric and diesel forklifts in terms of operation, price, maintenance, and advantages, so you can better choose the right warehouse forklift.

Forklifts Operation

Counterbalanced electric forklifts are very simple to operate. A shift lever on the left, similar to an electronic hydraulic gearshift, controls forward and reverse, while a joystick on the right controls the forklift’s side shift, tilt, rearward movement, and fork positioner.

Counterbalanced internal combustion forklifts come in both mechanical and automatic models. The shift lever on the mechanical model is located on the right, alongside the other joysticks. For unfamiliar operators, operating a mechanical diesel forklift can be clumsy. The gearshift on an automatic diesel forklift is located on the left side of the steering wheel. Pushing forward moves forward, and pushing backward moves reverse. The joystick for controlling other forklift functions is also on the right side.

Diesel forklifts can also be customized with an electronic hydraulic gearshift on the steering wheel, which is an upgrade over mechanical or automatic models.

Price of forklifts

The price of an electric forklift is primarily determined by the body steel, motor, and battery. The battery and motor costs account for a significant portion of the forklift’s cost. A larger battery capacity means longer operating time, but also a higher price. We are a professional forklift manufacturer and support custom large-capacity batteries, including maintenance-free lead-acid and lithium batteries.

After years of development, the diesel forklift market has become increasingly complex, with significant price and quality variations. Engines that meet Euro V and US EPA standards also contribute significantly to the price of a forklift.

Forklift price comparison: Electric forklifts are cheaper than diesel forklifts of equivalent quality, but used diesel forklifts are generally more stable than electric forklifts.

Repair and Maintenance

Electric forklifts are relatively simple to maintain, requiring only routine maintenance of the battery and motor. However, long-term use can lead to oil seal aging and leakage, a common forklift problem. Simply replacing the seals can effectively resolve this issue.

Internal combustion forklifts require more complex maintenance, requiring regular replacement of fuel, oil, and air filters. This is like regularly cleaning out toxins and debris from the vehicle’s interior to ensure smooth operation.

Comparison of the Advantages of Electric and Diesel Forklifts

Electric forklifts offer advantages in affordability, ease of maintenance, and environmental friendliness. You can own a quality forklift for a relatively low price. Furthermore, they use electricity, which is much cheaper than gasoline, saving you significant purchase and fuel costs.

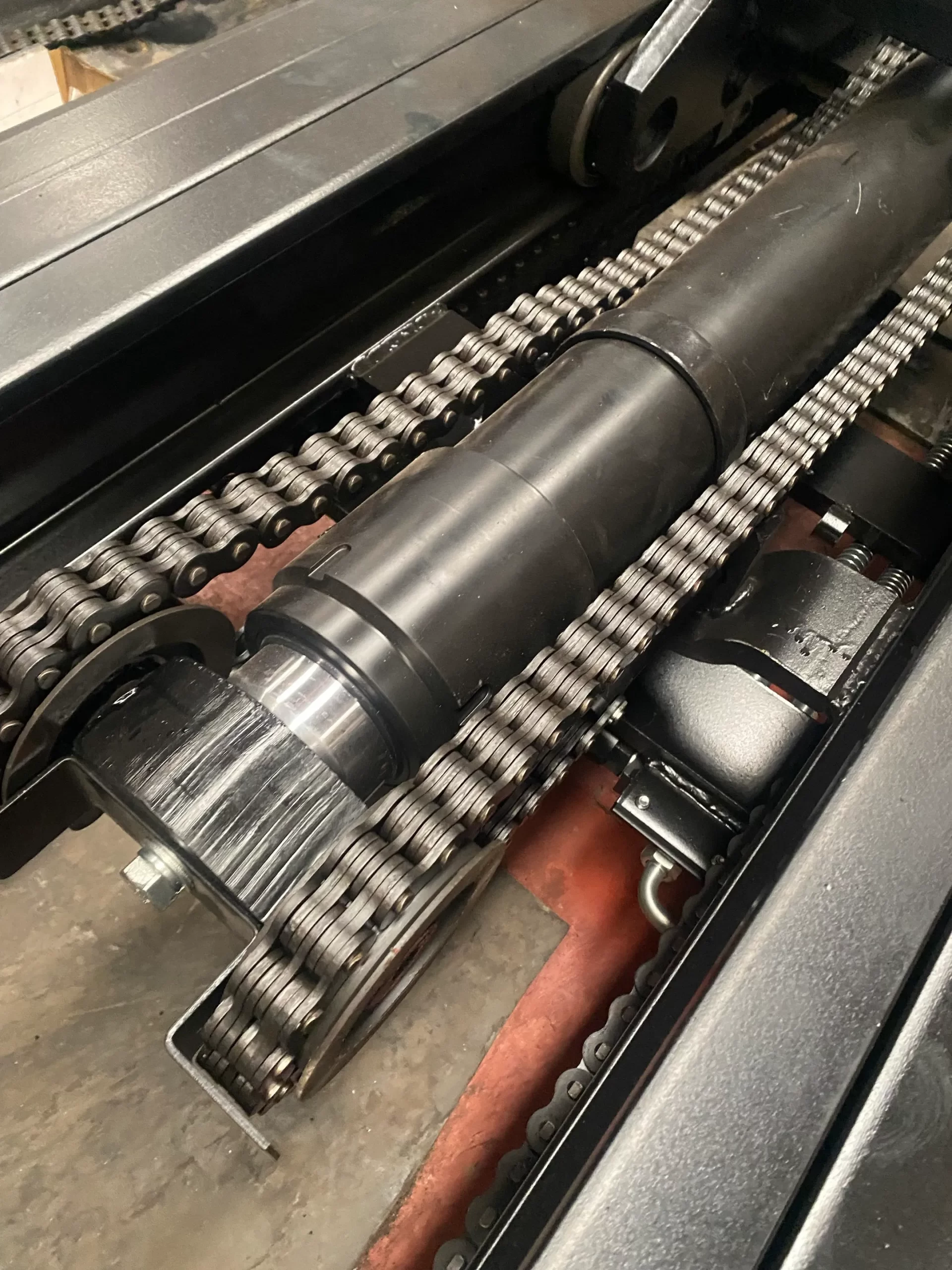

The advantages of diesel forklifts are that, while high-quality diesel forklifts are slightly more expensive than electric forklifts, they have more powerful engines, can lift heavier objects with increased throttle pressure, and can last longer. While maintenance is slightly more demanding, they offer a more cost-effective and stable performance for long-term use. Our diesel forklifts offer the following features and advantages: a widened mast significantly enhances the driver’s forward visibility; the mast, seven-section thickened chain, and hydraulic cylinder are designed for high strength, providing a strong overload capacity; mast heights of various sizes are available; and highly wear-resistant pneumatic tires are standard. An LCD display, comfortable seats, rearview mirrors, bright LED lights, and a buzzer are standard features.

Disadvantages of Electric Forklifts

Electric forklifts also have their disadvantages, primarily because the battery drains over time and requires replacement. Our batteries support 3,000 charge and discharge cycles, providing at least five years of service.

Electric forklifts are more suitable for indoor use. Most electric forklifts are not suitable for rainy weather, as rainwater can seep into the circuits and cause short circuits.

Daily operating hours are limited, and the operating time of an electric forklift is determined by the battery capacity. Current technology cannot yet achieve the 24-hour standby capability of a diesel forklift. However, there are solutions. You can increase the battery capacity to increase the operating time of the forklift, or you can equip a second battery for backup.

Summary

The price of an electric forklift is directly proportional to its quality; you get what you pay for. You can choose a larger battery to extend its lifespan. Imagine buying an electric forklift of the same quality and tonnage for half the price compared to a diesel forklift. This is a truly worthwhile investment for forklift users. Attention to routine maintenance can significantly extend the lifespan of your electric forklift.

If you’re looking for long-term value and superior lifting capacity, choose a high-quality diesel forklift. We are a professional forklift manufacturer and can provide you with high-quality diesel forklifts.